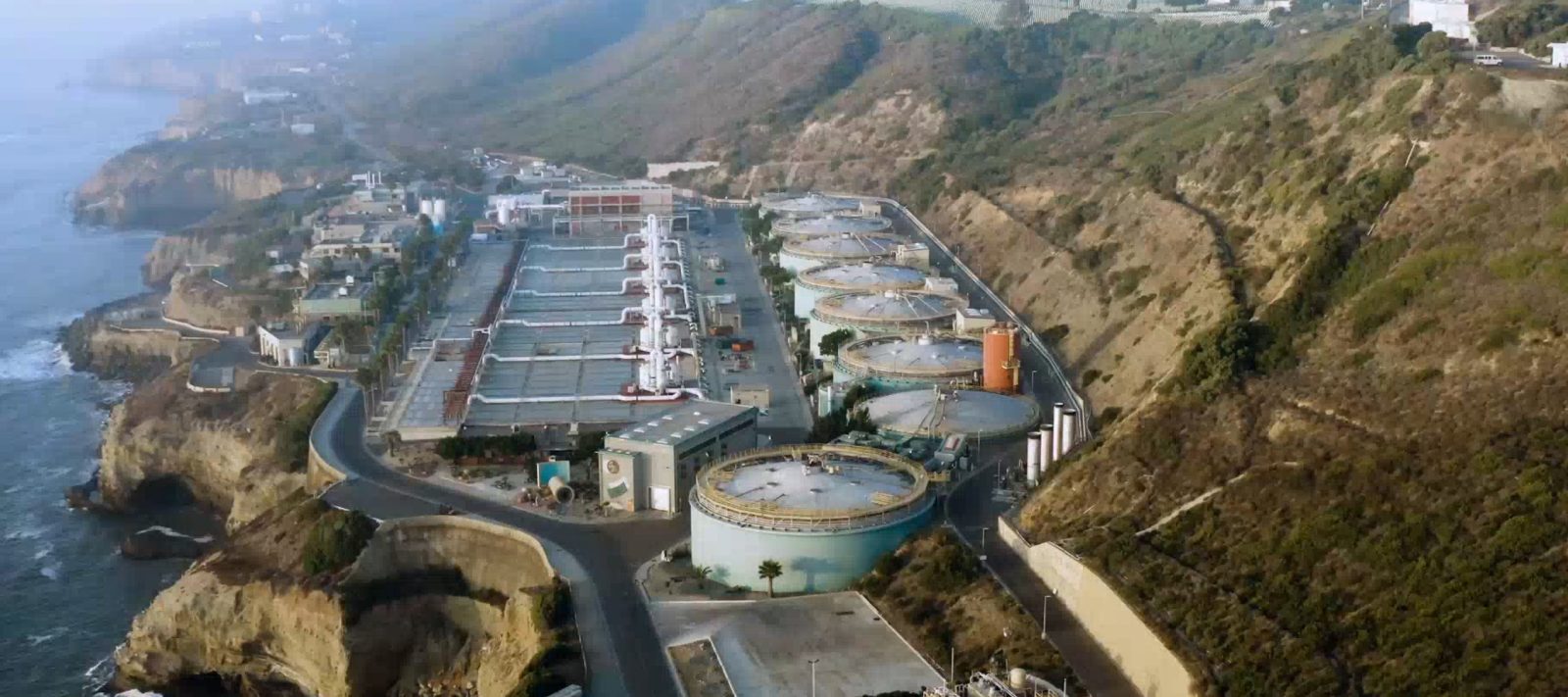

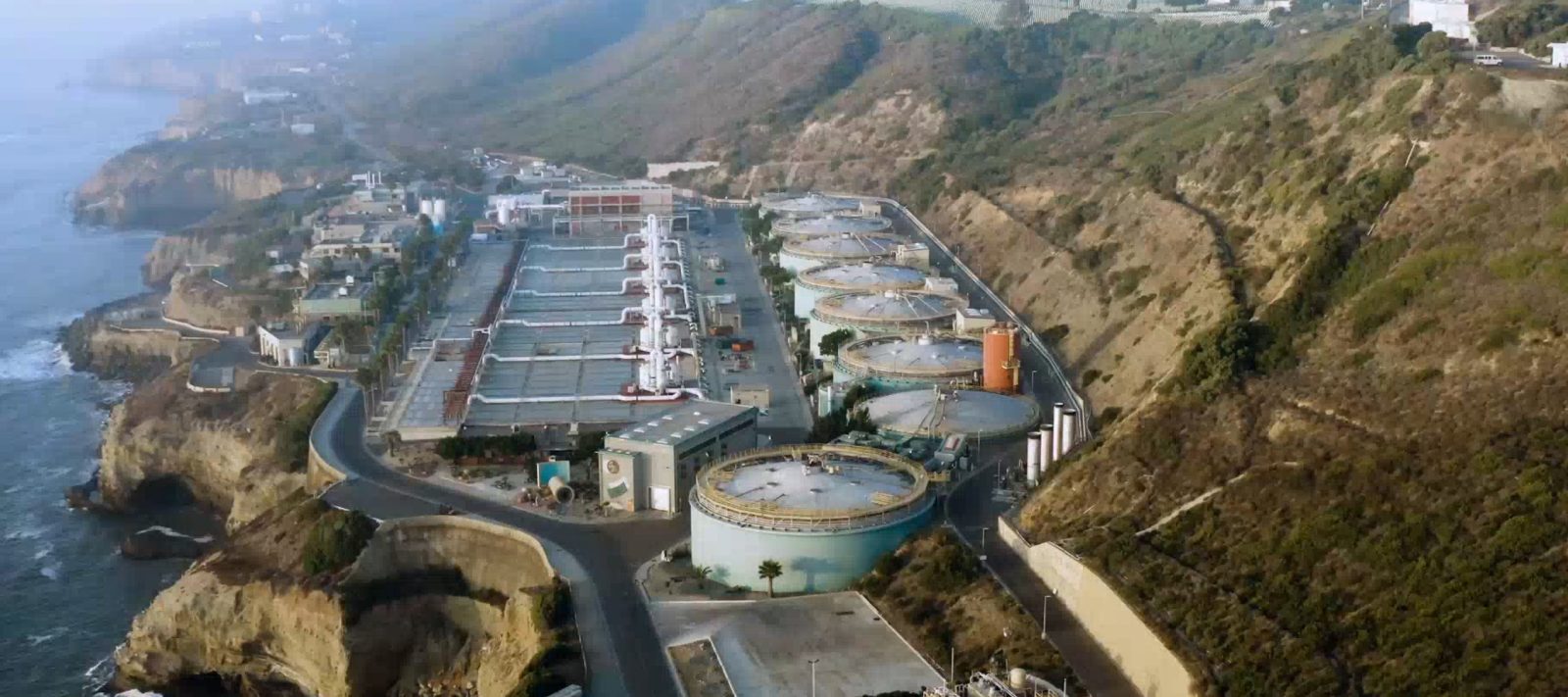

Durable tanks ready to withstand rigorous wastewater service requirements

Proven Capabilities

Our cost-efficient, durable tanks are designed and built to satisfy the rigorous service requirements of wastewater. We have the proven experience and customization capabilities to provide storage solutions throughout the wastewater collection and treatment process. In every case, we make sure to gain a deep understanding of your needs and adapt our tanks to provide the most effective solution.

A tank for every application.

Specialized for Wastewater

Wastewater storage comes with its own unique demands and considerations and DN Tanks has the expertise and flexibility to seamlessly meet them. We coordinate with equipment manufacturers to incorporate wastewater process design requirements into our wastewater solutions, such as:

Equalization Storage

- Odor Control Systems

- Automated or Manual Tank Cleaning Systems

- Mixing Systems

Digesters

- Mixing Systems

- Fixed or Floating Steel Covers

- Membrane Covers

- Concrete Domes

- Internal Piping

- Gas Collection Equipment

- Stairway and Catwalk Systems

Sludge Storage

- Mixing Systems

- Internal Piping

- Stairway and Catwalk Systems

- Concrete or Aluminum domes

Clarifiers

- Concrete, Stainless or Fiberglass Launders

- Clarifier Mechanism

- Stairway and Catwalk Systems

- Concrete or Aluminum Domes

WHAT OUR CLIENTS SAY

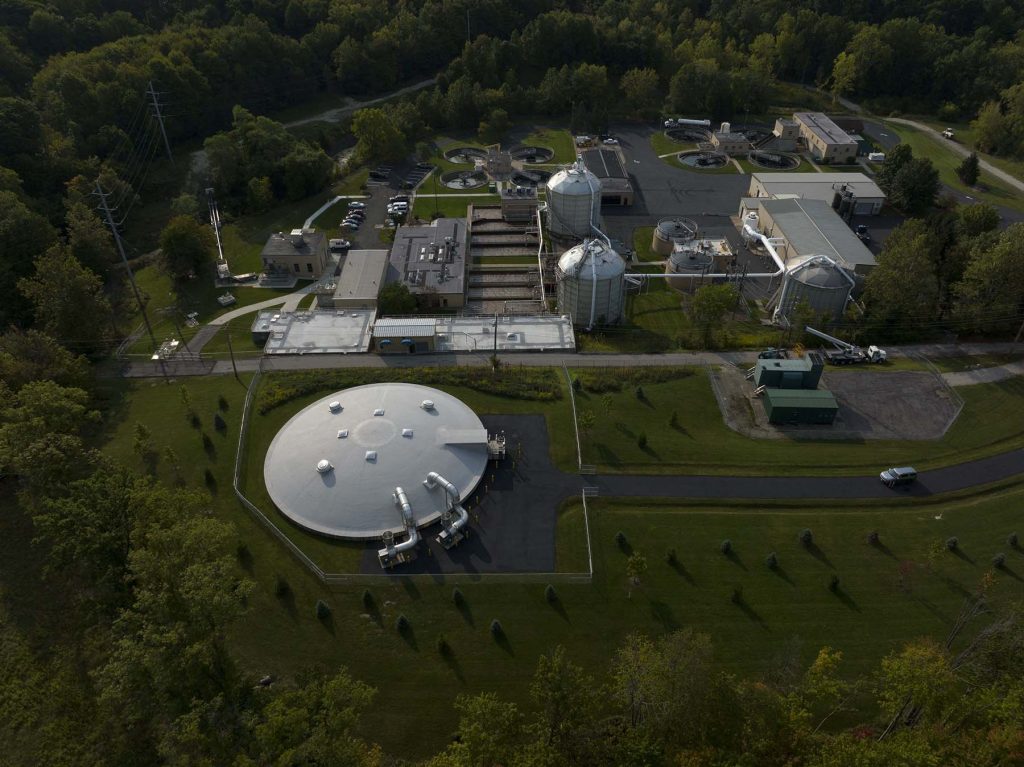

Working with DN Tanks was a pleasure. In my 40 years, I've never worked with such a professional company and competent team. The DN Tanks team, lead by Ray Candee, ran an incredibly efficient and safe process - we really enjoyed working with them and watching the tank go up.”

Paul Solanics, Director, Water Reclamation Department

City of Solon, OH

Using both our long-standing industry knowledge and our employee's institutional knowledge, DN Tanks understands the specific design challenges associated with each unique wastewater / stormwater application.

WASTEWATER STORAGE PROJECTS ALL BUILT TO STAND THE TEST OF TIME

Our regional managers are available to answer all of your questions.